0102030405

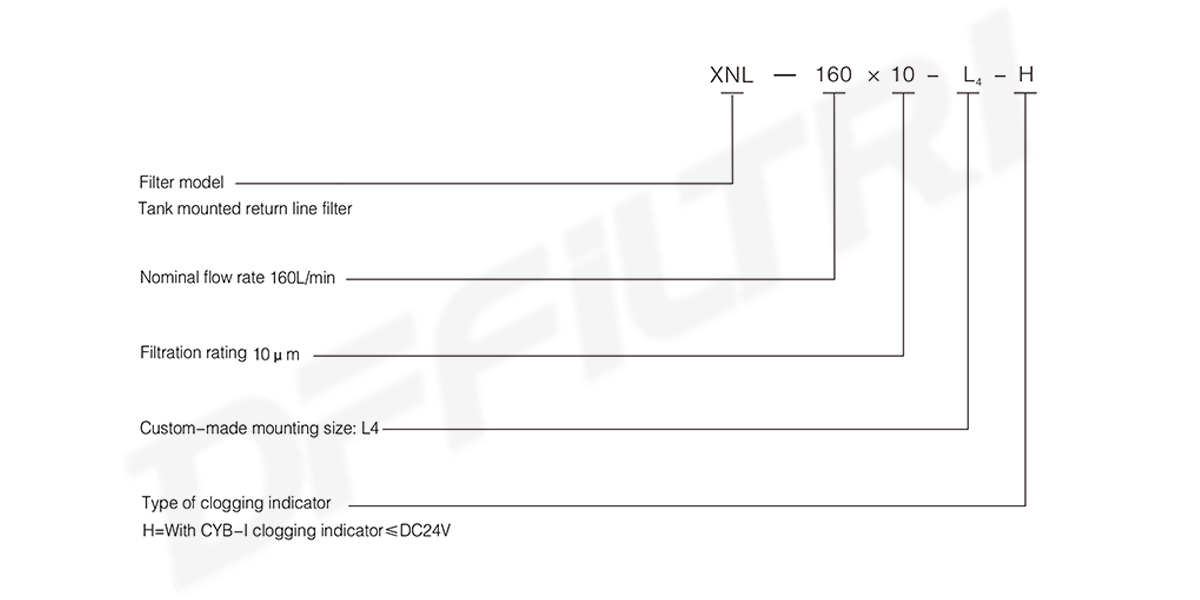

XNL tank mounted l return line filter series

Introduction to XNL tank mounted l return line filter series

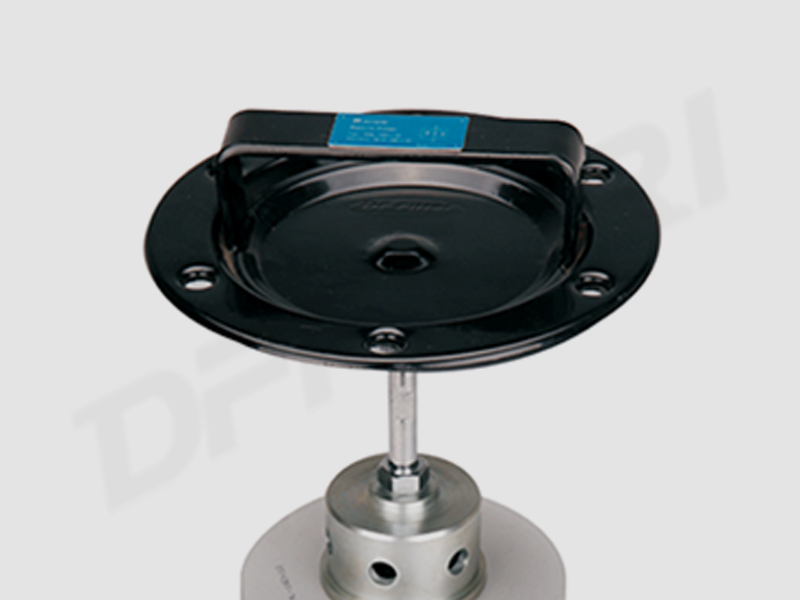

The XNL tank mounted l return line filter series is installed at the hydraulic system oil return port to filter out metal particles and rubber pollutants generated by component wear in the hydraulic system, keeping the oil flowing back to the tank clean.

XNL tank mounted l return line filter series features

The XNL tank mounted l return line filter series has the following significant characteristics:

1. Directly installed inside the fuel tank simplifies the system's piping, saves space, and makes the system layout more compact

2. Equipped with a self closing valve: When repairing the system, the oil in the tank will not flow back. When replacing the filter element, the pollutants inside the filter element can be carried out of the fuel tank together, so that the oil will not flow out.

3.Equipped with a bypass valve: When the filter element is blocked by pollutants, the pressure difference reaches

4.At 0.35 Mpa, if the filter element cannot be replaced immediately, the bypass valve located at the top of the filter element will automatically open (with a pressure difference of 0.4 Mpa) to protect the normal operation of the system. 4. Equipped with magnetic device: it can filter out 1 in the return oil and liquid μ Ferromagnetic particles above m.

| Model | Nominal flow rate (L/min) | Dia (mm) | Nominal pressure (bar) | Filtration rating ( μm) | Type of indicator | oress ofthe bypass valve (bar) | Model of element | Weight (kg) |

| XNL | 25 | 20 | 6 | Optional

3,5,10 20,30 βx(c)optional 75,100,200,1000, in accordance with ISO16889 |

H=CYB-I

clogging indicator≤ DC24V G=CY-Il clogging indicator ≤220V Omit :Without indicator |

Setting 4 | NLX-25x* | 1.2 |

| 40 | NLX-40x* | 1.5 | ||||||

| 63 | 32 | NLX-63x* | 2.3 | |||||

| 100 | NLX-100x* | 2.5 | ||||||

| 160 | 50 | NLX-160x* | 4.6 | |||||

| 250 | NLX-250x* | 5.1 | ||||||

| 400 | 80 | NLX-400x* | 10.1 | |||||

| 630 | NLX-630x* | 10.8 | ||||||

| 800 | 90 | NLX-800x* | 14.2 | |||||

| 1000 | NLX-1000x* | 14.9 |

Application scope of XNL tank mounted l return line filter series

TheXNL tank mounted l return line filter series has a wide range of applications, mainly including metallurgy, petrochemicals, thermal power and nuclear power, mechanical processing equipment and other fields. At the same time, it can also be applied in industries such as chemical, petroleum, pharmaceuticals, automobiles, light industry, food, mineral processing, water treatment, electroplating, dyes, textiles, etc.

When users choose the XNL tank mounted l return line filter series, they must be equipped with a pressure transmitter. When the filter element is blocked by dirt to a pressure difference of 0.35Mpa, the filter element should be replaced in a timely manner.

In summary, the XNL tank mounted l return line filter series is an efficient and reliable filtering equipment, and its wide application range makes it an important component of hydraulic systems in many industries.