0102030405

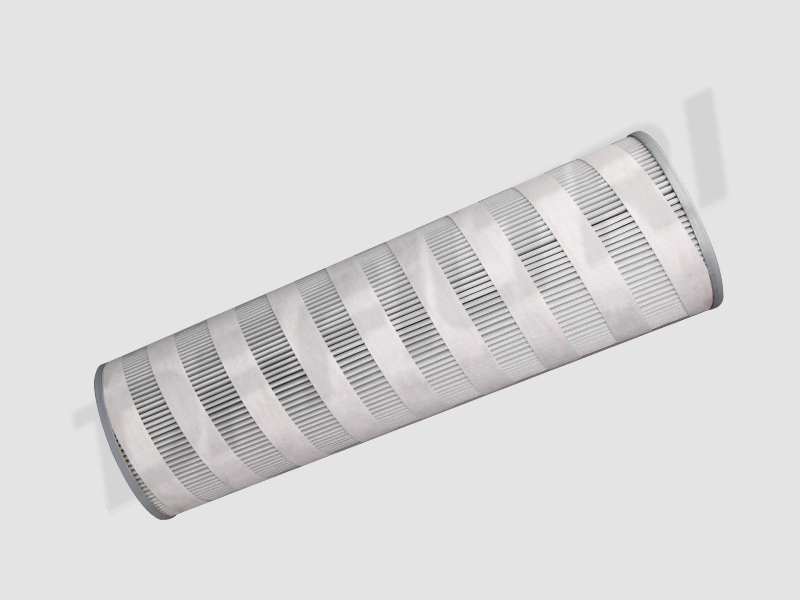

Tank built-in return filter series

Introduction to the Tank built-in return filter series

The built-in oil return filter in the oil tank is a filtering device installed inside the hydraulic oil tank of a hydraulic system. Its main function is to filter out pollutants generated or invaded in the system, such as metal particles, rubber, etc., before the oil returns to the tank, in order to maintain the cleanliness of the oil in the tank.

Characteristics of the Tank built-in return filter series

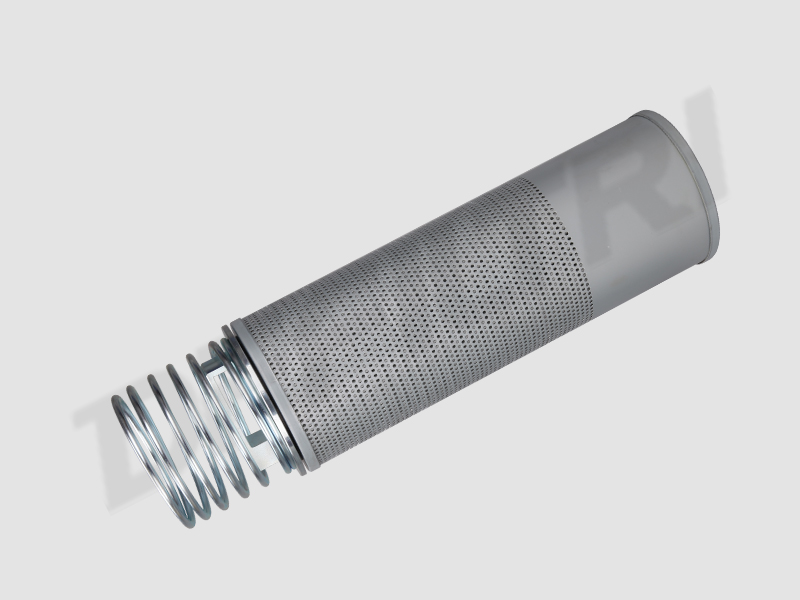

1. Directly installed inside the fuel tank: simplifies the system piping, saves space, and makes the system layout more compact.

2. Self closing valve design: When repairing the system or replacing the filter element, it can effectively prevent oil from flowing out of the tank and maintain the sealing of the oil.

3. Bypass valve function: When the filter element is blocked by pollutants and the pressure difference increases, the bypass valve will automatically open to protect the normal operation of the filter element and system. This function is usually triggered when the pressure difference reaches a certain value (such as 0.35 MPa to 0.4 MPa).

4. Magnetic device: Some models have built-in magnetic devices that can filter out ferromagnetic particles above 1 μ m in the oil, further improving the cleanliness of the oil.

5. Liquid flow diffuser: helps the return oil flow smoothly into the oil tank, reduces bubble generation, reduces pollutant disturbance, and improves filtration efficiency.

6. Various filter cartridge materials: Common filter cartridge materials include fiberglass, paper, mesh, and line gap, among which fiberglass filters are widely used for their high filtration accuracy and oil permeability.

|

Factory model |

Original pressure loss(bar) |

Flow rate L/min |

Filtration rating(μm) |

Cracking pressure of by pass valve |

Φd |

H1 |

H |

ΦD1 |

ΦD2 |

ΦD3 |

| HYLQ-05 | 1.2 | 450 |

Optional 5、10、20 βx(c) 75、100、 200、1000 in accordance with ISO 16889 |

Setting 2bar |

7 | 85.5 | 450 | Φ110 | Φ125 | Φ150 |

| HYLQ-05B | 1.2 | 450 | 7 | 85.5 | 450 | Φ110 | Φ125 | Φ150 | ||

| HYLQ-05C | 1 | 800 | 7 | 79 | 500 | Φ110 | Φ125 | Φ150 | ||

| HYLQ-05D | 1 | 1100 | 7 | 79 | 550 | Φ110 | Φ125 | Φ170 | ||

| HYLQ-05E | 1.2 | 1000 | 7 | 79 | 450 | Φ110 | Φ125 | Φ140 | ||

| HYLQ-05F | 1 | 800 | 7 | 79 | 500 | Φ110 | Φ125 | Φ150 | ||

| HYLQ-05G | 1.2 | 450 | 6 | 79 | 400 | Φ75 | Φ94 | Φ120 | ||

| HYLQ-05H | 1 | 1300 | 7 | 79 | 600 | Φ110 | Φ125 | Φ170 | ||

| HYLQ-05M | 1 | 1200 | 7 | 79 | 450 | Φ110 | Φ125 | Φ170 | ||

| HYLQ-05N | 1 | 1200 | 7 | 85.5 | 550 | Φ110 | Φ125 | Φ170 | ||

| HYLQ-05Q | 1 | 630 | 7 | 79 | 450 | Φ100 | Φ125 | Φ150 | ||

| HYLQ-05R | 1 | 400 | 7 | 79 | 420 | Φ110 | Φ125 | Φ150 | ||

| HYLQ-05S | 1 | 850 | 7 | 79 | 550 | Φ110 | Φ125 | Φ170 | ||

| HYLQ-05V | 1.2 | 450 | 7 | 85.5 | 450 | Φ110 | Φ125 | Φ150 | ||

| HYLQ-05W | 1 | 350 | 7 | 79 | 362 | Φ110 | Φ125 | Φ150 |

Performance of the Tank built-in return filter series

1. Filtering accuracy: Depending on the specific model and purpose, the filtering accuracy can reach 2, 5, 10, and 20 microns. Users can choose or specify according to their actual work needs.

2. Work pressure: Usually able to withstand high work pressure, such as up to 10 bar or higher, to ensure stable operation in high-pressure environments.

3. Working temperature: It has a wide range of adaptability and can operate normally within the temperature range of -30 ° C to+110 ° C.

4. Flow range: To meet the needs of different systems, the limit flow can range from 30L/min to 2000L/min.

Usage scenarios of the Tank built-in return filter series

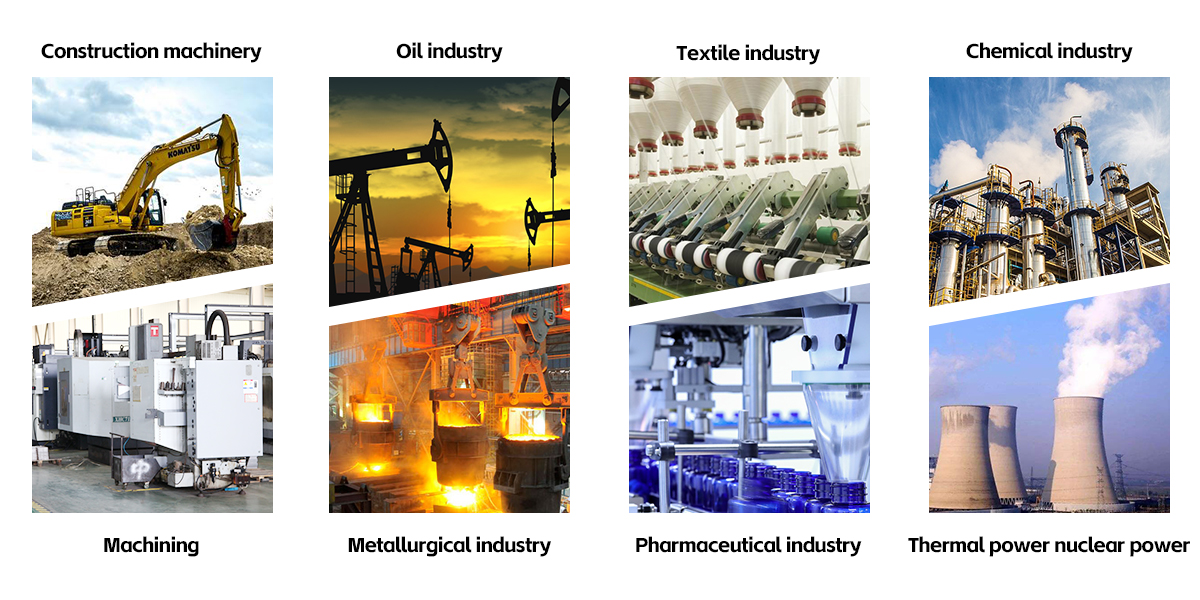

The built-in oil return filter in the fuel tank is widely used in various hydraulic systems, especially in situations where high requirements are placed on oil cleanliness. Specifically including but not limited to:

1. Metallurgical industry: used for filtering hydraulic systems such as steel mills and continuous casting machines.

2. Petrochemical industry: separation and recovery of products and intermediate products in refining and chemical production processes.

3. Textile industry: Purification and uniform filtration of polyester melt during the drawing process.

4. Electronics and pharmaceuticals: pre-treatment filtration of reverse osmosis water and deionized water, pre-treatment filtration of detergent and glucose.

5. Thermal power and nuclear power: purification of oil in lubrication systems, speed control systems, and bypass control systems of gas turbines and boilers.

6. Mechanical processing equipment: lubrication systems and compressed air purification for papermaking machinery, mining machinery, injection molding machines, and large precision machinery.

In summary, the Tank built-in return filter series in the fuel tank plays an important role in hydraulic systems due to its unique design, excellent performance, and wide range of application scenarios.