0102030405

RFB check valve magnrtic return filter series

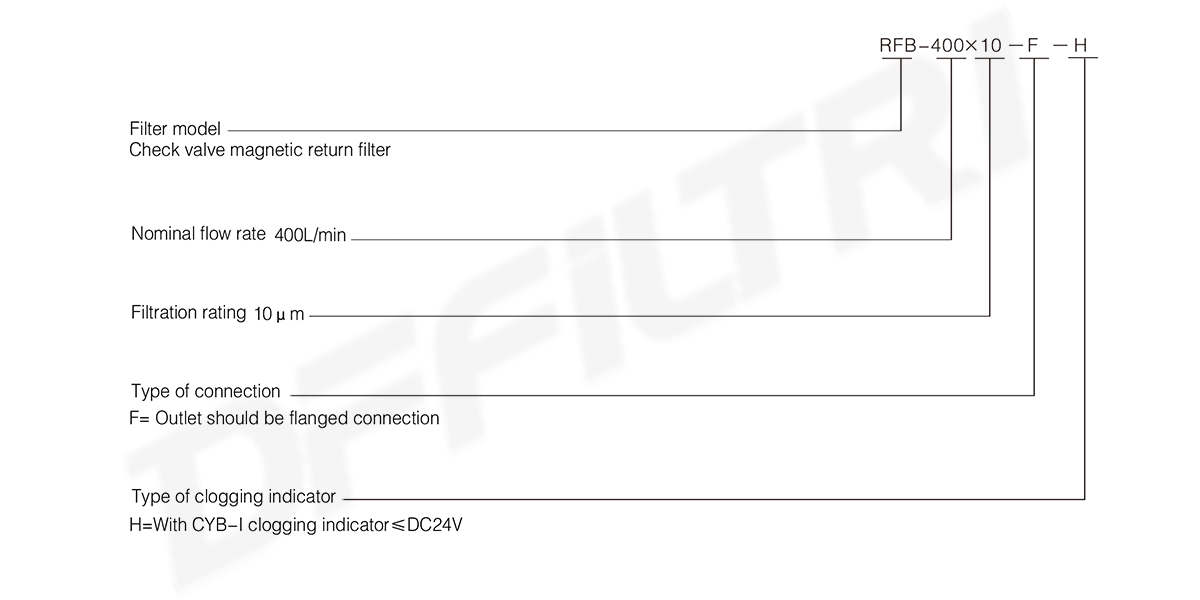

Introduction to RFB check valve magnrtic return filter series

The RFB series direct return self sealing magnetic return oil filter is used for fine filtration of hydraulic system return oil, filtering out metal particles caused by component wear and rubber impurities caused by seal wear in the hydraulic system, keeping the oil flowing back to the tank clean.

| Model | Nominal flow rate (L/min) | Type of connection | Dia (mm◇ | Nominal pressure (bar) | Cracking pressure of the bypass valve (bar) | Filtration rating (μm) | Type of indicator |

Model of element | Weight (kg) |

| RFB | 25 | F=

Flanged connection |

55 | 16 | Setting 4 | Optional

3,5,10,

20,30... Bx(c)Optional 75,100,200,1000, in accordance with ISO16889 |

H=CYB-1 clogging indicator≤DC24V G=CY-Il clogging indicator ≤220V Omit :Without indicator | FBX-25x* | 4.6 |

| 40 | 55 | FBX-40x* | 4.8 | ||||||

| 63 | 55 | FBX-63x* | 5.3 | ||||||

| 100 | 55 | FBX-100x* | 6 | ||||||

| 160 | 55 | FBX-160x* | 6.7 | ||||||

| 250 | 80 | FBX-250x | 12.3 | ||||||

| 400 | 80 | FBX-400x* | 14.7 | ||||||

| 630 | 80 | FBX-630x* | 17.3 | ||||||

| 800 | 80 | FBX-800x* | 18.6 | ||||||

| 1000 | 30 | FBX-1000x* | 21.3 | ||||||

| 1300 | 80 | FBX-1300x* | 27.8 |

Performance and characteristics of RFB check valve magnrtic return filter series

1. The RFB check valve magnrtic return filter series

can be directly installed on the top, side, or bottom of the oil tank. The filter head is exposed outside the oil tank, and the cylinder is partially immersed in the oil tank, simplifying the system pipeline and making the system layout more compact.

2. The RFB check valve magnrtic return filter series is equipped with a permanent magnet, which can filter out ferromagnetic particles of more than 1 micron in the oil.

3. The RFB check valve magnrtic return filter series has a bypass valve: when starting with cold oil, due to factors such as low system liquid temperature and flow pulsation, the pressure difference of the filter is too large, and the main engine cannot work. In case the filter element is blocked by pollutants, the bypass valve in parallel at the bottom of the filter cover will automatically open (with an opening pressure of 0.4MPa) to protect the normal operation of the filter element and system.

4. The RFB check valve magnrtic return filter series has a check valve: the filter is placed on the side or bottom of the oil tank, and the oil in the tank will not flow out when replacing the filter element.

5. The RFB check valve magnrtic return filter series is equipped with a liquid flow diffuser, which, together with the lower part of the cylinder, can ensure that the return oil flows smoothly into the oil tank without producing bubbles, reducing the re entry of air and weakening the disturbance of accumulated pollutants. When the bypass valve is opened, it can also play a coarse filtering role.

6. Equipped with a visual indication and electrical communication device, overflow pipe, and accumulation cup;

After the filter element gradually becomes clogged, the clogging situation of the filter element can be observed on the visual gauge, and at the same time, an electric signal can be connected (with a signal value of 0.35MPa). Install an overflow pipe and a fouling cup at the bottom of the filter element, which can be carried out together with the filter element when replacing it, thus avoiding the phenomenon of pollutants falling back into the oil tank.

7. The filter element is made of glass fiber, which has the advantages of high filtration accuracy, large oil flow capacity, small original pressure loss, and large pollutant absorption. Its filtration accuracy is calibrated with absolute filtration accuracy for filtration ratio β 3, B5, 10, β 20 ≥ 200, filtration efficiency n ≥ 99.5%.

The evaluation methods are ISO16889-99 and GB/T18853-2002.

8. The RFB check valve magnrtic return filter series has the characteristics of easy installation, connection, and replacement of filter elements: the oil inlet is flange connected. For the installation flange between the filter head and the oil tank, users can design and process 6 flange screw holes on the oil tank plate according to the dimensions in the chart. Loosen the top cover of the filter to replace the filter element or add oil to the fuel tank.

9. The RFB check valve magnrtic return filter series has an attached oil return hole: there are two small oil return holes on the side and top of the filter head, which can be used for filtering a small amount of oil back into the oil tank or adding a small amount of oil to the oil tank in the system. When the filter is installed on the side or bottom of the oil tank, the small hole cover can be loosened to remove the oil containing pollutants inside the filter, thereby extending the service life of the filter element and promoting oil purification.