0102030405

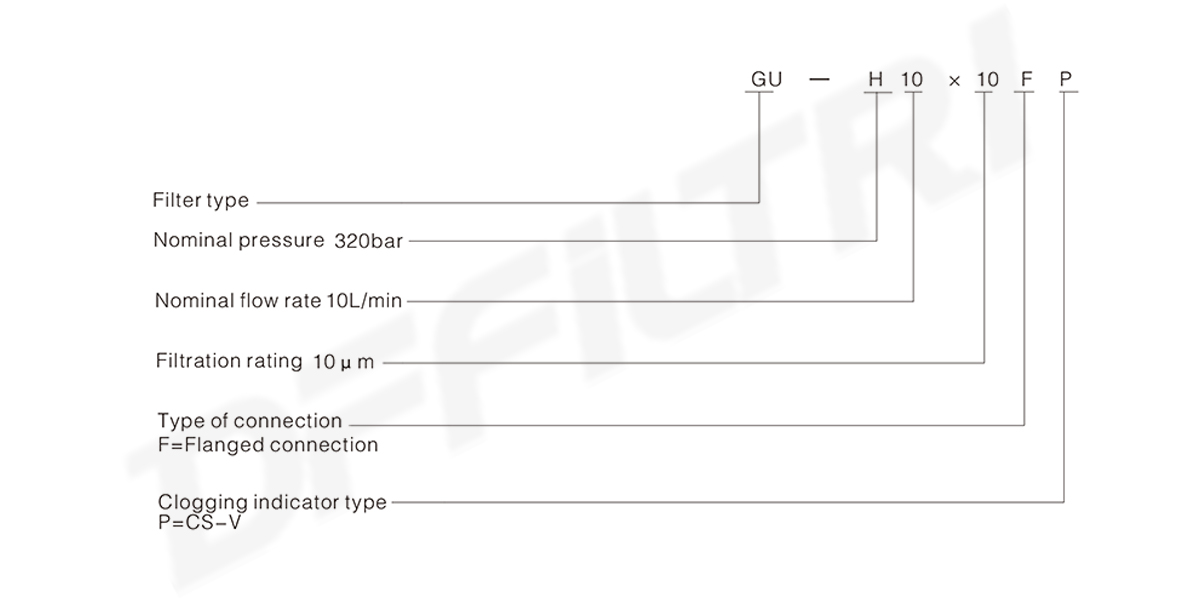

GU-H check valve pressure line filter series

Introduction to GU-H check valve pressure line filter series

The GU-H check valve pressure line filter series is a filtering equipment designed specifically for hydraulic systems. It is installed on the pressure pipeline of the hydraulic system and is mainly used to remove or prevent mechanical impurities mixed in hydraulic oil, as well as gum, asphalt, carbon residue, etc. generated by the chemical changes of the hydraulic system itself. By filtering out these impurities, the GU-H check valve pressure line filter series can prevent valve core jamming, blockage of throttle holes, gaps, and damping holes, as well as rapid wear of hydraulic components, thereby ensuring the normal operation of the hydraulic system and extending the service life of the equipment.

Characteristics of GU-H check valve pressure line filter series

1. Differential pressure transmitter function: When the filter element is contaminated and blocked until the pressure difference at the inlet and outlet reaches 0.35MPa, the differential pressure transmitter will send a switch signal to remind operators to clean or replace the filter element in a timely manner to ensure system safety.

2. Bypass check valve: When the filter element is contaminated and blocked to a pressure difference of 0.4MPa, or other reasons cause the pressure difference at the inlet and outlet of the filter to be too large, the bypass valve can automatically open to ensure the normal operation of the system. When cleaning or replacing the filter element, the bypass valve can also prevent system oil backflow, prevent oil loss in the pressure pipeline, and prevent air and pollutants from entering the system.

3. High filtration accuracy: The filter element adopts a new type of chemical fiber filtration material, which has the advantages of high filtration accuracy, large oil flow capacity, small original pressure loss, and large pollutant capacity. Its filtration accuracy and efficiency meet relevant standards and can effectively filter out impurities in the oil.

| Model | Nominal flow rate (L/min) | Nominal pressure (bar) | Filtration rating (μ m) | Pressure loss (bar) | Indicator type | Cracking pressure of the bypass vaive(bar) |

Model of element | Connection | Weight (kg) | |

| Initial | Max | |||||||||

| GU-H | 10 | 320 | Optional

3,5,10,

20,30... βx(c)Optional 75,100,200,1000, in accordance with ISO16889 |

0.8 | 3.5 | P=CS-V Omit=Without clogging indicator | Setting 4 | GX-10x* | Omit=Threaded connection | 3.9 |

| 25 | GX-25x* | 5.3 | ||||||||

| 40 | GX-40x* | 8.4 | ||||||||

| 63 | 1 | GX-63x* | 10.2 | |||||||

| 100 | GX-100x* | 12.4 | ||||||||

| 160 | 1.5 | GX-160x* | F=Flanged connection | 18.7 | ||||||

| 250 | GX-250x* | 23.5 | ||||||||

| 400 | 2 | GX-400x* | 39.4 | |||||||

| 630 | GX-630x* | 42.6 | ||||||||

GU-H check valve pressure line filter serie features

The GU-H check valve pressure line filter series performs excellently. It can work stably under high pressure and various temperature environments, with a working pressure of up to 32Mpa and a working temperature range of -10 ℃ to 100 ℃. In addition, the filter also has the characteristics of compact structure, easy installation, and simple maintenance, which can adapt to the needs of various hydraulic systems.

The GU-H check valve pressure line filter series is widely used in various hydraulic systems, including hydraulic systems of machine tools, excavators, injection molding machines, and other equipment. In these application scenarios, it can effectively protect hydraulic components from wear and blockage, improve equipment reliability and service life.