Scope of use of hydraulic oil tank

Hydraulic oil tanks play a crucial role in hydraulic systems, with a wide range of applications and important functions. Reasonable selection, use, and maintenance of hydraulic oil tanks can ensure the normal operation of hydraulic systems and extend the service life of equipment.

1、 Application Fields

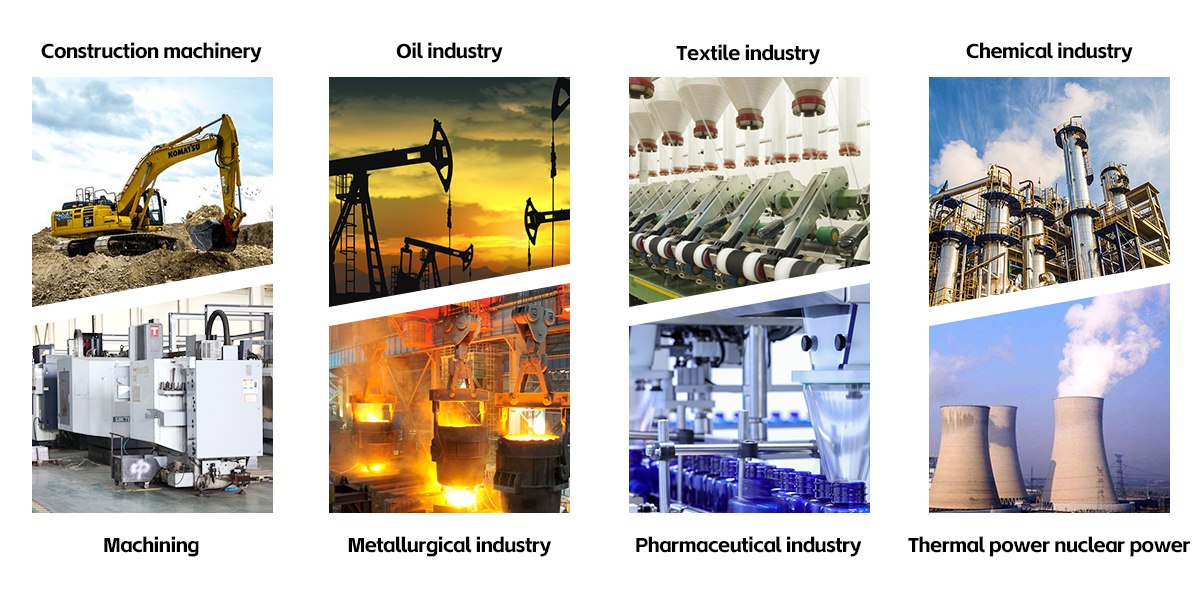

Hydraulic oil tanks are widely used in various equipment and systems that require hydraulic transmission or control, including but not limited to:

Industrial machinery, such as injection molding machines, die-casting machines, punching machines, machine tools, etc., often rely on hydraulic oil tanks to store and supply hydraulic oil in their hydraulic systems.

Construction machinery: excavators, loaders, cranes, rollers, etc. During the operation of these heavy equipment, the hydraulic oil tank provides a stable supply of oil to the hydraulic system, ensuring the normal operation of the equipment.

Agricultural machinery: tractors, harvesters, rice transplanters, etc. Hydraulic oil tanks also play an important role in these devices, supporting various functions of the hydraulic system.

Aerospace: In the aerospace field, although hydraulic systems are relatively complex and highly demanding, the importance of hydraulic oil tanks as key components for oil storage and supply is self-evident.

Ship and Ocean Engineering: Hydraulic oil tanks are also widely used in various types of ships and ocean engineering equipment to provide stable power support for hydraulic systems.

2、 Main functions

The main functions of a hydraulic oil tank include:

Storage of sufficient hydraulic working medium for hydraulic transmission system: Ensure that the hydraulic system has sufficient oil supply during operation.

Provide installation locations for components in hydraulic transmission systems: The hydraulic oil tank is designed with installation locations for various components to facilitate system integration and maintenance.

Sedimentation of pollutants in hydraulic working medium: Through the sedimentation and filtration mechanism in the oil tank, impurities and pollutants in the oil are reduced.

Air escaping into the hydraulic working medium: keep the purity and stability of the oil, and prevent oil foam caused by air mixing.

It should be able to effectively prevent the invasion of external pollutants: by sealing and filtering devices, external dust, moisture and other pollutants are prevented from entering the fuel tank.

Relieve the heat generated during the operation of the hydraulic transmission system: The heat dissipation design of the oil tank helps to reduce the temperature of the oil, improve the efficiency and stability of the system.

3、 Type and Structure

Hydraulic oil tanks can be classified into various types based on their structure and purpose, such as open and closed oil tanks, integral hydraulic oil tanks, and separated hydraulic oil tanks. Different types of fuel tanks have differences in design and use, but they are all designed to meet the needs of hydraulic systems and optimize their performance.

4、 Precautions for use

When using a hydraulic oil tank, the following precautions should be taken:

Keep the tank ventilated: keep the tank well ventilated during refueling to avoid foam of oil.

Regularly clean the fuel tank: Regularly clean the interior of the fuel tank to remove accumulated impurities and pollutants.

Regularly replace the oil: According to the usage of the equipment and the manufacturer's recommendations, regularly replace the oil to ensure its quality and performance.

Prevent the intrusion of air and pollutants: Take effective measures to prevent air and pollutants from entering the interior of the fuel tank.